The explaination that I have disliked the most for 99% of my life is, “Because everyone else does it this way.” An adopted (from Bertrand Russell) mantra of my life has been, “The fact that an opinion has been widely held is no evidence whatever that it is not utterly absurd; indeed in view of the silliness of the majority of mankind, a widespread belief is more often likely to be foolish than sensible." I absolutely believe that statement: regarding subjects from technology to economics to politics to community/religion. I will always assume that “everyone else” is probably a moron, especially if the thing we’re talking about has any aspect of opinion involved. Often, it turns out that I’m wrong. Sometimes the reason people have done something the same way for a long time is that it is the most efficient, practical, easiest, and even effective way to do that thing. Sometimes I’m right and the reason people have been doing something the same way for a 1,000 years is because they are lazy, superstitious, ignorant, timid/conservative, and/or mentally challenged. With only one life to live and a limited amount of time, energy, and patience with which to live it, I am often uninspired to spend much effort worrying about why things “have always beend one this way.” That is not always (or even often) a strength, it’s just a thing, a personality glitch.

For example, I put a lot of thought and effort into creating the smallest body design possible and still retain “balance.” I started with thicker material than I expected to need and installed a 1/2” cap over the wiring routing holes, creating an instrument from which I expected to carve a lot from the back to create a slight “wrap-around” feel. As the body approached completion and the neck was finished enough to attach, I started fooling with finding the point where the strap pins could be installed to make the instrument hang in a neutral, balanced, position. To my mind, that sounded more comfortable than the body-heavy designs of most guitars.

It also turned out that the sculpting I intended to do was unnecessary. My body design conformed so well that additional wood-removal was pointless. It would, however, have been a good exercise. So, I might build another bass using the same general design but taking the body-shaping further.

I also blew off the trait most of my fellow students had for pickup selection. First, it’s a bass and, second, this instrument is one I built purely for my own enjoyment and playing. I’m not a particularly complicated bass player. I don’t solo, ever. I like being part of the rhythm section, in the background, just filling in the bottom. The pickup on my bass has a fairly simple task: provide as much fundamental as possible with as little noise as possible. I went for a Chinese knockoff of a Gibson humbucker design, primarily because the pickup came with individual coil wiring. When I received the pickup, I tested the two coils and found that one had slightly (10%) higher impedance and resistance. So, I unwrapped the coils and pulled wire off of that coil until it was very close to the other coil. I reassembled the pickup, soaking the winding in wax before retaping it, coated the pickup pocket and wiring channels in magnetic paint, and hooked up the pickup for series and parallel operation with a single DPDT switch. Add a volume control and a jack and that’s all I need; along with a mostly-midpoint pickup position. I never use the bridge pickup, so why install one?

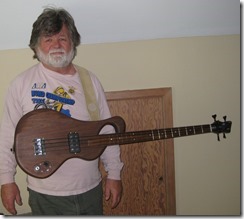

You can see that my body shape is unconventional. It works beautifully, by the way. It is comfortable standing or sitting and the “handle” is a lot more useful than a horn.