When I was a working engineer and, later, an engineering manager, my least favorite answer to any question was always, “Because everyone does it that way.” For the last 50 years, a mantra of mine, and my current email signature, has been a Bertrand Russell quote, “The fact that an opinion has been widely held is no evidence whatever that it is not utterly absurd; indeed in view of the silliness of the majority of mankind, a widespread belief is more often likely to be foolish than sensible." More than often this is true, but occasionally my kneejerk reaction to convention takes me, the hard way, through the processes that others have already explored and I discover sometimes things are always done pretty much the same way for a reason. Sometimes that reason is bullshit, but there is often a core assumption to be evaluated that with my limited-to-non-existent visual skills I can not see until I experiment.

My baseline bass is a Steinberg L-Series headless and almost body-less bass. I’ve owned a couple of these instruments in the last thirty years and, currently, own and play a Hohner knock-off of this bass. I love everything about my Hohner from the low weight to the perfect balance to the sound. The only thing I don’t love is the look, which is always a heavily enameled solid color body and neck with a rosewood fingerboard. If the guitar is going to be made from wood, which my Hohner is and my Steinbergers were not. The headless design was not an option for the first year guitar design course. One of the failures from my acoustic guitar build was my original intention to make my instrument from all-domestic wood. I screwed up my first two walnut fingerboards and my one-piece walnut neck block and had to start over quickly, so I snagged a slab of quarter-sawn rosewood and a mahogany neck block from a guitar builder who was dumping material stock cheap and those two critical parts of the instrument ended up coming from imported wood.

This time, I wanted to avoid that and my design was for all walnut; partially because I love the look of walnut and partially because I wanted to take a second look at a design I started almost 40 years ago. That design was based on the B.C. Rich Mockingbird body and incorporated a fretless Fender Precision neck. Considering my rookie woodworking status, that instrument came out pretty well, except that it weighed close to 50 pounds. I started with a 2” thick piece of old growth walnut that I’d milled myself from rough walnut stock I’d found in a friend’s barn. For my current instrument, I wanted everything I’d accomplished with that original instrument without the physical stress. Literally, my bandmates called my old bass “the refrigerator” because between the bass and the Star roadcase, hauling that thing up a flight of stairs was a lot like carrying a refrigerator with one hand. It currently resides in my daughter’s music room where no one has played it for decades. Honestly, it was a terrific bass, sonically, but it will cut a groove in your shoulder that will bisect the player if given enough time.

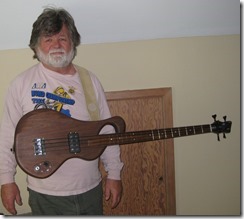

The picture at left shows what balanced looks like. The guitar hangs perfectly neutral when the neck is parallel to the ground. This sort of defeats about 50% of the reason I designed in that “handle” at the top of the instrument, but I thought balance was more important than justifying my design geekiness. Turns out, balanced is not particularly comfortable in a bass, at least for me. While my Steinberger/Hohner L-Series instruments are, in fact, balanced, a slight increase in headstock weight makes a body-heavy strap positon a lot more desireable. For one, I have short limbs (and fingers) and I end up pulling the neck up and slightly to my right when I play the bass. So, I repositioned the neck pin as far up that “handle” as possible, which is pretty much exactly where everyone else on the planet puts a neck strap pin. The end result was a much more comfortable balance and a more relaxed playing position. Which, of course, everyone who has built an electric guitar in the last 75 years knew before I decided to test traditional thinking.

No comments:

Post a Comment